How High-Quality Bag Formers Improve VFFS Performance and Reduce Operational Costs

Vertical form-fill-seal (VFFS) equipment plays a vital role in modern packaging operations. Every minute of downtime impacts productivity, labor, and shipment schedules. While many factors influence machine performance, one component affects consistency more than most: the bag former. When manufacturers rely on precision-engineered forming sets, they experience smoother production, cleaner seals, and more efficient film usage. This blog explains how high-quality bag formers improve packaging output, reduce waste, and support long-term operational success.

Why Bag Formers Matter in High-Speed Packaging

A bag former shapes flat film into a perfect tube as it moves through the VFFS machine. If the geometry is exact, the film tracks correctly and forms strong, consistent seals. When the forming set is worn or poorly engineered, film wrinkles, jams, and alignment problems slow the entire line.

Bag formers affect nearly every stage of the packaging cycle:

- Film tension and tracking

- Speed and efficiency

- Seal appearance and strength

- Waste levels

- Overall equipment reliability

Because of this, investing in a precision-built forming set provides measurable value for any production facility using VFFS systems.

Common Production Challenges That Quality Bag Formers Help Solve

Packaging teams face recurring issues that disrupt efficiency. High-quality formers address these problems directly and maintain stable performance throughout long shifts.

1. Film Tracking Problems

Film that drifts left or right leads to poor registration, weak seals, and waste. A well-designed bag former guides the film smoothly and keeps the material centered. Its polished surfaces reduce drag and minimize friction. When operators use a forming set engineered to exact specifications, tracking issues drop significantly.

2. Difficulty Maintaining Speed

Running VFFS equipment at full speed demands precise film control. When a former creates excess drag, operators must slow down the machine to prevent tearing or jamming. High-quality formers maintain uniform tension so the equipment can perform at rated capacity. The result is more throughput without added strain.

3. Inconsistent Packages

Customers expect professional, clean, repeatable packaging. If the tube created by the former is not shaped correctly, finished bags vary in appearance. This inconsistency affects brand perception and can even cause seal failures. With a precision former, package quality becomes stable and predictable.

4. Excess Film Waste

Film waste adds unnecessary cost to production. Misalignment, improper shaping, and friction points all contribute to scrap. A well-engineered former reduces the amount of material needed per bag and prevents wasted film caused by jams or rework.

5. Frequent Changeovers and Downtime

Operators lose significant time when changeovers require adjustment or troubleshooting. A forming set built to the original equipment dimensions fits perfectly, reducing setup time. When the former matches the machine’s specifications, operators spend less time correcting issues and more time producing.

How High-Quality Bag Formers Reduce Total Operational Costs

Although premium forming sets require investment, they pay for themselves through improved efficiency and lower maintenance. Facilities that adopt precision formers see gains in productivity and reductions in scrap. The improvements come from several key advantages.

Longer Equipment Life

Durable materials and polished internal surfaces lead to fewer film snags and scratches. This reduces everyday strain on the VFFS machine and helps equipment last longer.

Lower Scrap Rates

Even a small reduction in wasted film has a major financial impact over thousands of production hours. Better film guidance means fewer mistakes and less rework.

Faster Production Speeds

When a machine runs without interruptions, it produces more units per hour. A quality bag former supports high throughput by maintaining stability even at top speeds.

Less Operator Intervention

Fewer adjustments mean operators can focus on oversight rather than troubleshooting. This shift improves labor efficiency and reduces the chance of human error.

Using a high-quality bag former supports a more reliable packaging operation. It leads to cleaner seals, better product presentation, and higher production output.

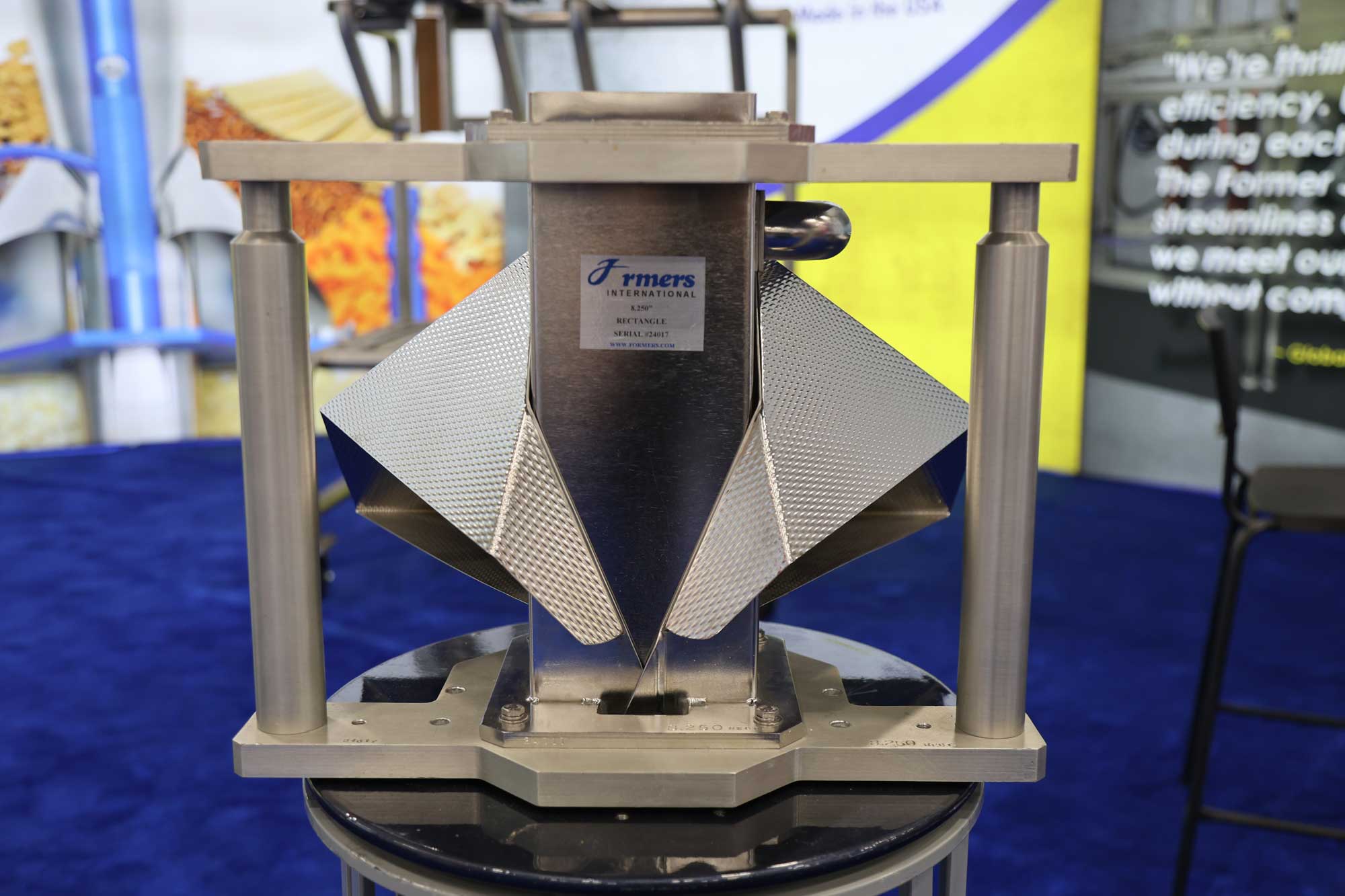

Why Choose Formers International

Formers International designs and manufactures precision-engineered bag formers compatible with major VFFS brands worldwide. Our forming sets help packaging teams improve performance, reduce downtime, and maintain consistent bag quality. We use advanced fabrication techniques to ensure every former meets the highest standards. When companies need dependable forming solutions, they trust Formers International to deliver accuracy, durability, and long-term value.

Your packaging equipment performs best when equipped with components built for exactness. By choosing our forming sets, you gain a long-lasting solution that keeps your line running at peak efficiency.

For more information or to request a quote, visit https://formers.com/quote/